Bad hardware components lie behind many failures in medical devices, according to Oshri Cohen, CEO of Cybord. The devices contain tens of computer chips and other components, so measuring quality becomes a tedious process.

Compounding the difficulty of measuring quality is the constant churn of components. Take personal computers. Two generic laptops sitting on the shelf from one of the big manufacturers could have very different components, because these manufacturers diligently depress costs by seeking the cheapest components from month to month.

Medical devices, while more high-end, also mix and match. They also suffer the risk of getting knock-off components from unethical vendors simulating more high-quality components.

Cybord has found a way to use cameras and AI-driven analysis to automate quality checks. A manufacturer can run each device through Cybord’s system, which in about one minute can scan all the components and return a quality report. The report shows each component in use with meta-information such as the manufacturing date. Sometimes, the component is not what its label claims it is, a clear problem.

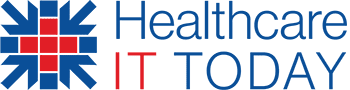

Damage or poor quality can also be identified by running the image of each component through the AI-generated model. Examples of damage the model can detect include defects in the component or how it is set into the device, as well as corrosion, oxidation, and mold (Figure 1). Of course, the model can also complain if the image is too blurry to analyze.

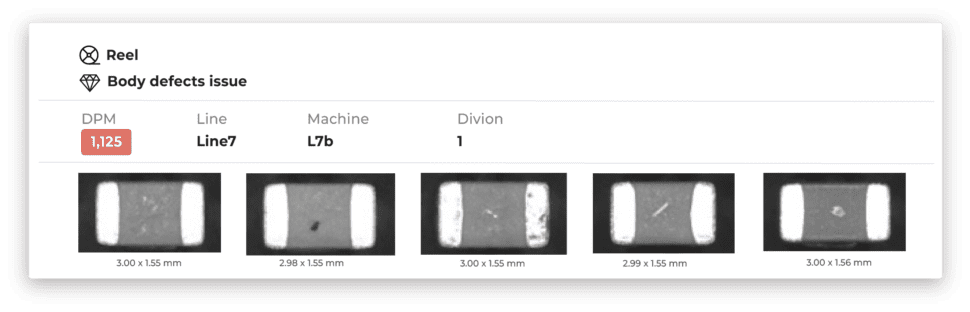

Many manufacturers run all devices that come off the assembly line through the Cybord process, so that bad components can be discarded and never make it out into the field to fail. The manufacturer can also use the data to evaluate their manufacturing process and check whether their vendors are honest. Cybord provides dashboards to help them evaluate large quantities of analytic results (Figure 2).

Cybord worked with the manufacturers to scan thousands of components, using the images to train the AI model.

The current high-profile alarms over AI, while worth investigating, often make us lose sight of the enormous benefits AI can bring. Cybord can dramatically reduce medical device failures out in the field. That should also noticeably reduce the costs of modern medicine and improve outcomes.